Gas Recovery

General process description

Helium is an indispensable element in numerous industrial applications, but its availability is also extremely limited. In view of this challenge, it is crucial to use resources sparingly and promote sustainability.

Our recovery systems play a central role in this by collecting helium from various processes fully automatically and recycling it so that it can be used again.

Depending on how contaminated the gas is, our Gas Purification Plant can purify helium back to a purity level of 6.0. In this way, we ensure that your processes can always operate at maximum efficiency and purity.

Recovery Compressor

Oil Water Sepearation

High Pressure Analysis Panel

High Pressure Distribution Panel

High Pressure Storage

Customer/Experiment

Gas Balloon

Pure Gas Bundle

Gas Purification Plant

Hardfacts

Features

Best investment against rising helium prices

Customized design possible

Expandable at any time, ideally tailored to your requirements

Various systems available for quality measurement, preparation and mass counting

Easy operation

Fully automatic operation

Modular, compact design

Optimum processes

Longer running times for helium condensers and more precise balancing of the valuable gas helium are the demands placed on a helium recovery system. The system requirements can usually only be met through automation. Designing, automating and selecting the optimum components is one of our core competencies.

Intelligent balloon control

Thanks to non-contact level measurement, the balloon is hardly stressed, which has a positive effect on its service life. Longer compressor running times can be achieved to prevent condensation forming in the compressor oil.

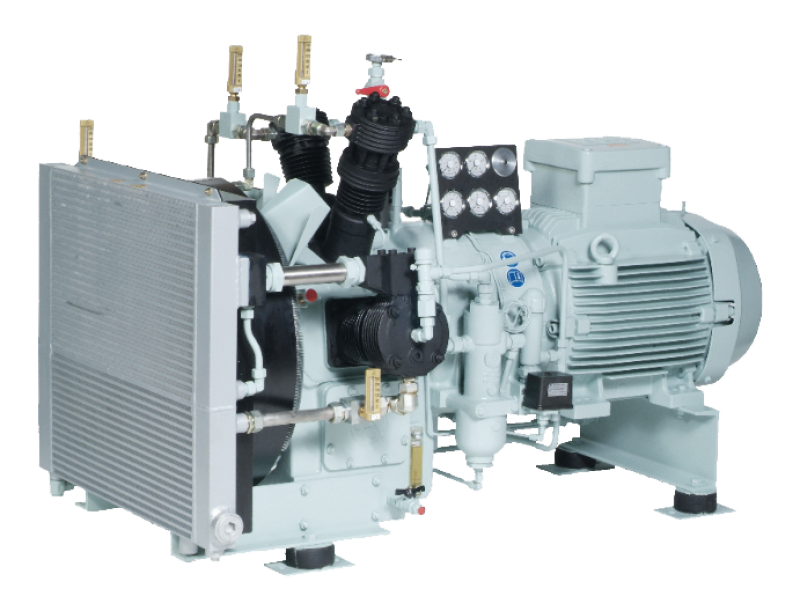

Compressors

Sauer & Sohn's range of helium compressors covers capacities from 16 - 406 m3/h. In conjunction with our control system, the lead compressor is determined on the basis of running hours in order to divide operating hours evenly between redundant compressors.

High pressure analysis panel HAP

The quality of the helium can also be measured and fed into a quarantine bundle if the level of contamination is too high. This increases system availability in particular, as helium contamination is quickly detected and overloading of the freeze-out cleaner is prevented. The gas from the quarantine bundle can be automatically fed to the balloon in metered quantities once the degree of contamination no longer affects the constant operation of the helium liquefier.

Automatic high-pressure distribution panel HDP

The helium is distributed to the various storage groups based on the pressure and can be balanced using the pressure loss.

Balancing

At low pressure, all lines leading to the balloon are fitted with gas meters. Another sensor records the gas volume at high pressure and the loss rate of the balloons, compressors and the regeneration dryer can be calculated using the calculation [ND_Gas_Volume - HD_Gas_Volume]. This prevents leaks and detects them immediately. In particular, the rotating compressors can also be continuously monitored.

Gas Purification Plant

Our GPP - Gas Purification Plant - is a highly complex gas purifier that purifies helium under high pressure up to helium 6.0. This helium can then be filled into cylinders or fed into the process. The GPP is low-maintenance and functions completely autonomously using LN2 - liquid nitrogen. It can be operated independently or in combination with our helium liquefier.

Standard scope of supply

- Gas meter

- Low pressure gas storage (balloon)

- compressors

- Control cabinet and SCADA system

- High-pressure separation

- High pressure storage

Contact

We have convinced you and you want further informations?