Gas liquefaction

General process description

Liquid helium is mainly used for cooling superconductors and for researching quantum effects in low-temperature physics. It also plays an important role in magnetic resonance imaging (MRI) and space travel for cooling magnets and rocket engines.

Our helium liquefiers are fully automatic, processor-controlled refrigeration systems with screw compressors and expansion turbines for liquefying helium. Contaminated gas can also be processed using the integrated purifier.

In classic applications, helium is used as a coolant or liquefied. Depending on requirements, we also supply systems with others that liquefy hydrogen or nitrogen.

Customer/Experiment

Mobil Dewar

Coldbox

LHe Dewar

Impure Gas Adsorber

High Pressure Storage

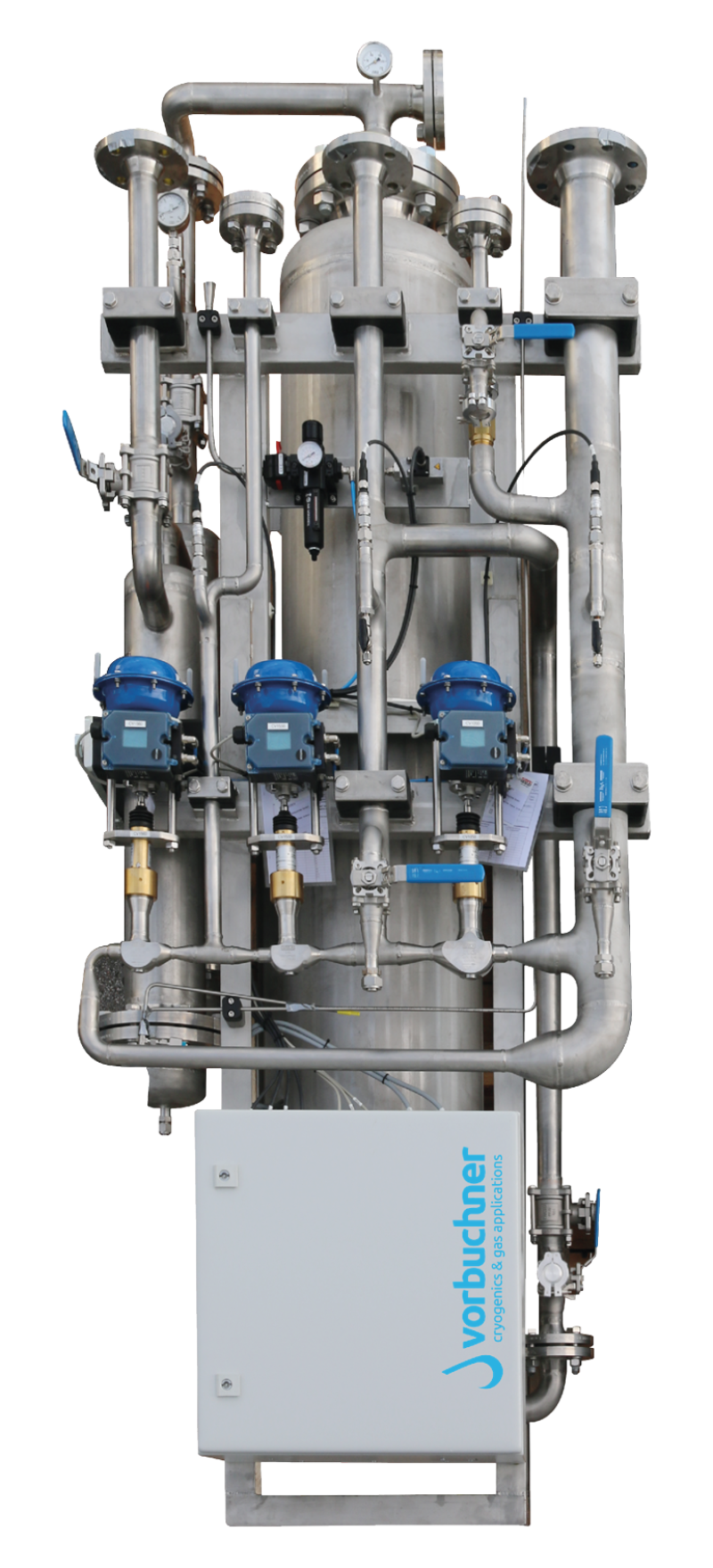

Gas Management System

Cycle Compressor

Pure Gas Buffer

Hardfacts

Features

Universal applicability (liquefier, refrigerator, radiant shield cooling)

Easy operation

Fully automatic operation

Automatic cleaner without external cooling

Modular, compact design

Extremely quiet and vibration-free

No special fastenings or foundations required

Optional - increased performance through LN2 pre-cooling

The cooling process

Cooling takes place according to the Claude process.

Compression

A screw compressor compresses purified helium from 1.05 to approx. 12.5 bar while constantly dissipating the resulting compression heat. Traces of oil are removed from the circulating gas by coalescer filters and a special oil absorber.

Expansion

The actual refrigeration is generated by two dynamic gas-bearing expansion turbines connected in series, whereby part of the cycle gas is expanded to perform work. In stationary operation, the final temperature after the second turbine is approx. 12 K.

At temperatures below 8 K, part of the cycle gas is expanded to approx. 1.3 bar by a Joule-Thomson valve (JT). This produces partly liquid helium with a temperature of approx. 4.5 K. In the transfer line, the 4.5 K cold helium is transported from the Joule-Thomson valve to the liquid helium tank.

Heat exchanger

The helium cold gas produced during expansion is used together with the low-pressure flow from the turbines in a counterflow principle to cool the hot gas and is circulated continuously. Aluminum plate heat exchangers are used for this purpose.

Freeze-out purifier

In order to avoid displacements due to frozen impurities in the process, only pure helium may be used in the liquefaction circuit. However, helium that is fed into the recovery system is contaminated with air, nitrogen or other gases. The diffusion of air in various components (gas bubble / gasometer) also has a negative effect on the gas quality. In helium liquefiers, integrated purification lines that use the cold from the process gas are usually aimed for. This has the advantage that no additional operating fluids such as LN2 are required. In addition, the contaminated helium can be cooled to approx. 30 K in order to freeze out residual contamination.

Contact

We have convinced you and you want further informations?