Liquefication | Recovery

Construction of a VL100 helium liquefier with recovery system, 80 L/h, at the WMI in Munich

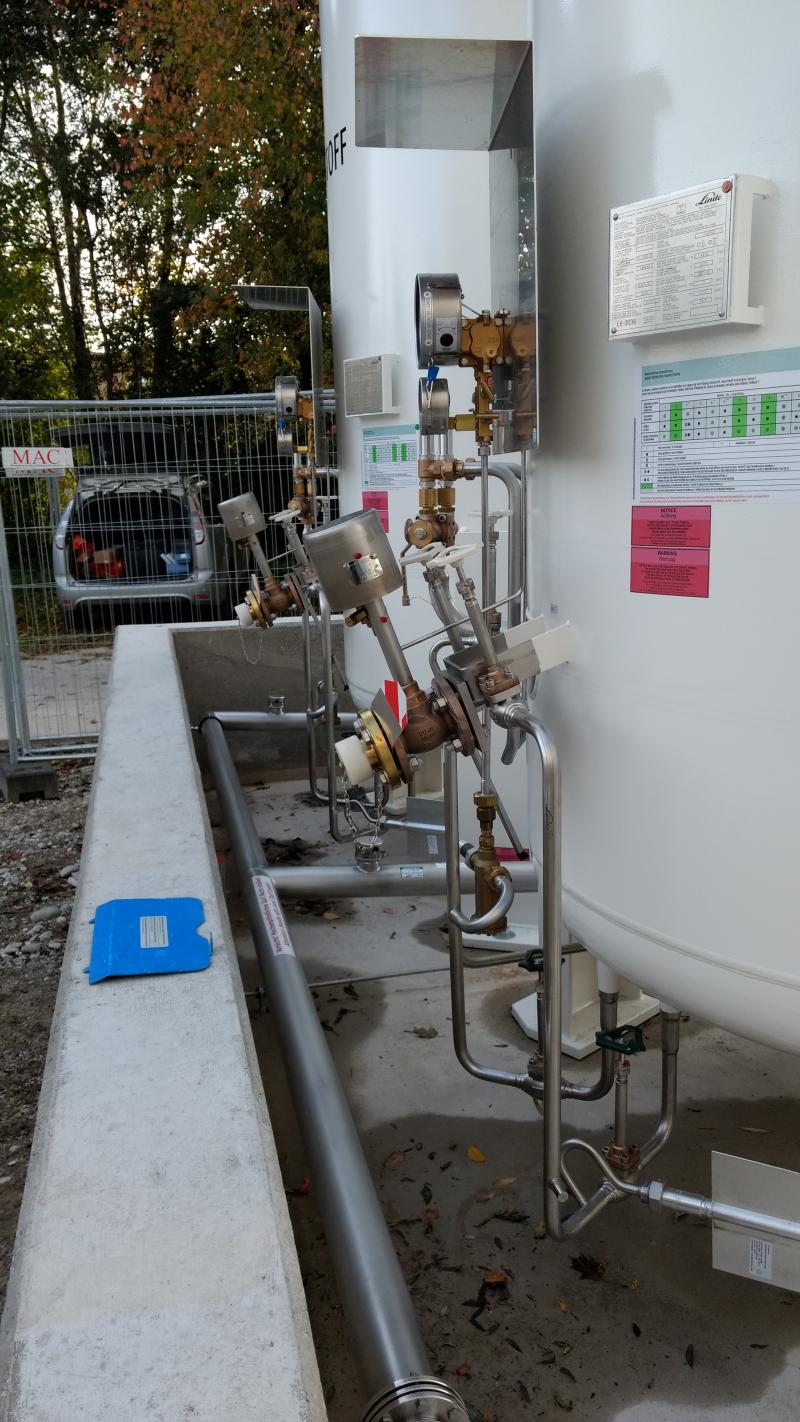

Design, manufacturing, assembly, and installation of a new helium liquefier with gas-bearing expansion turbines.

- Delivery of a Helium Liquefication Plant

- Cycle compressor, watercooled

- Oil Remover System with Gas Management Panel

- Coldbox incl. expansion turbines and freeze-out-purifier

- Gas dryer

- Process control technology (MSR)

- Installation of five new GHe storage tanks with a total volume of 60.000 l

- Installation of new LN2 storage tanks with a total volume of 12.000 l

- Automatic gas distribution with the helium distribution panel

- High-purity gas piping within the building

- Installation of all system components

- Commissioning of the entire system

- Maintenance of ongoing operations during conversion and construction phase, no significant losses

Realization date

03/2023Performance data

- Liquefication Rate:

- 30 l LHe/h without LN2 pre-cooling

- 80 l LHe/h with LN2 pre-cooling

- Compressor el. consumption: 90 kW

- Storage capacity GHe (geom. Volume): 5x 12.000 l á 200 bar

- Pure gas buffer: 2x 8.000 l á 16 bar / 1x 2.000 l á 16 bar

- Storage capacity LN2: 2x 6000 l

Contact

Walther-Meissner-Institut

Walther-Meissner-Str. 8

85748 Garching, Munich